|

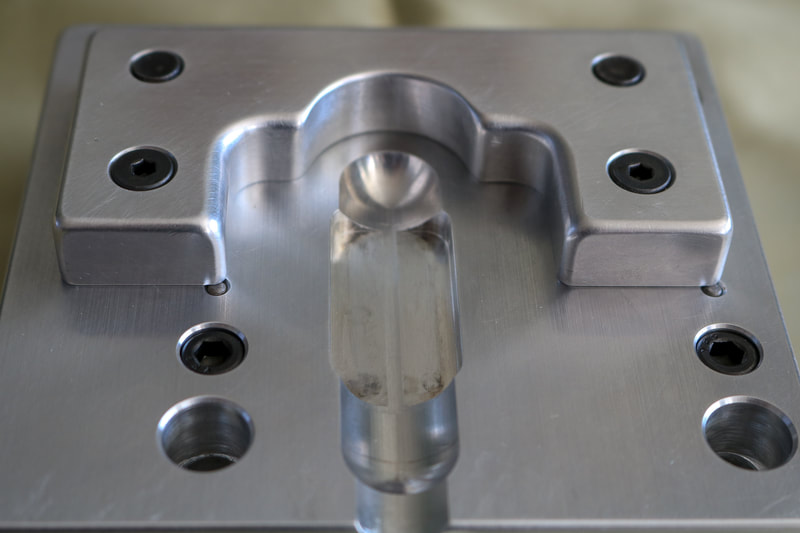

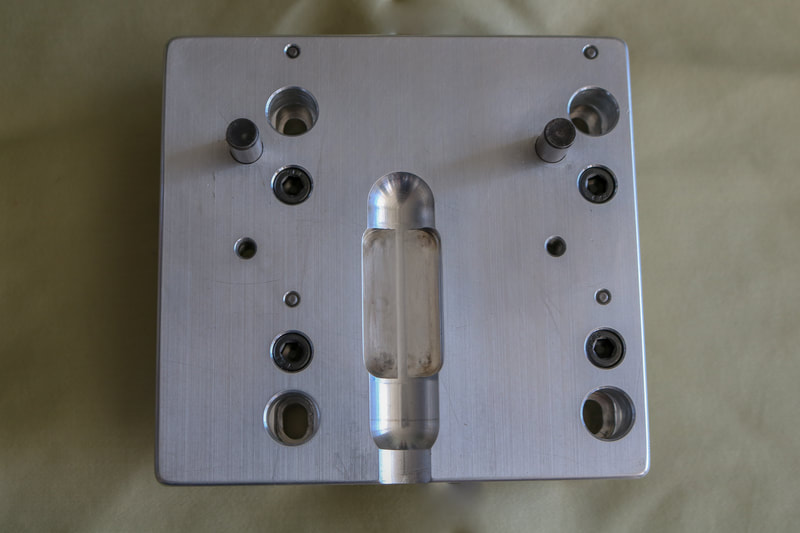

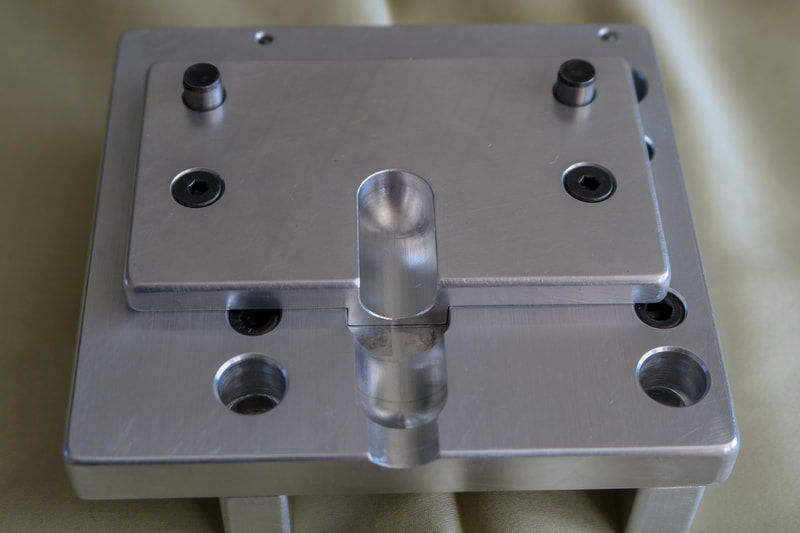

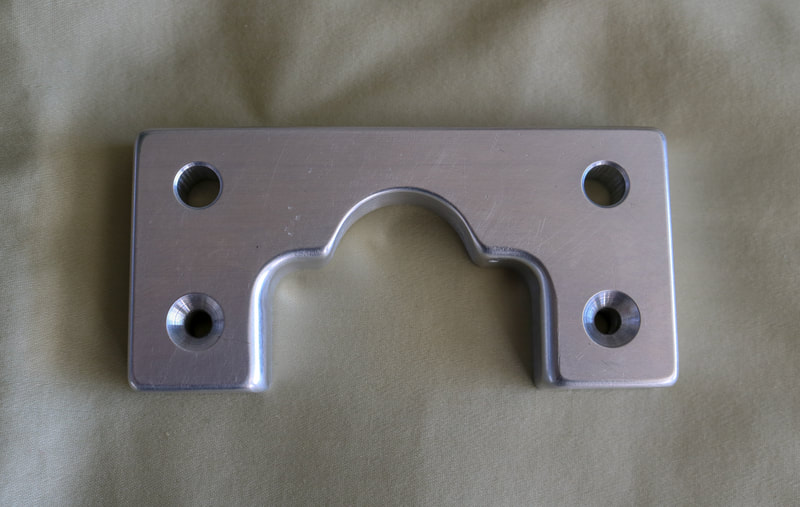

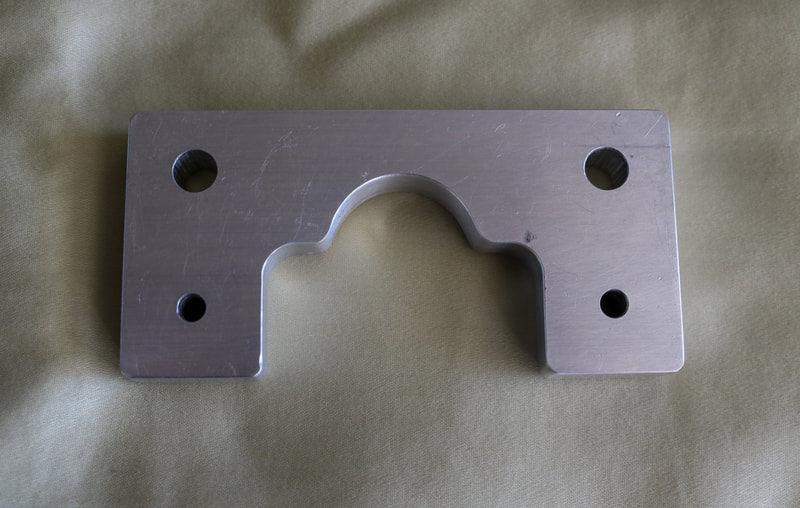

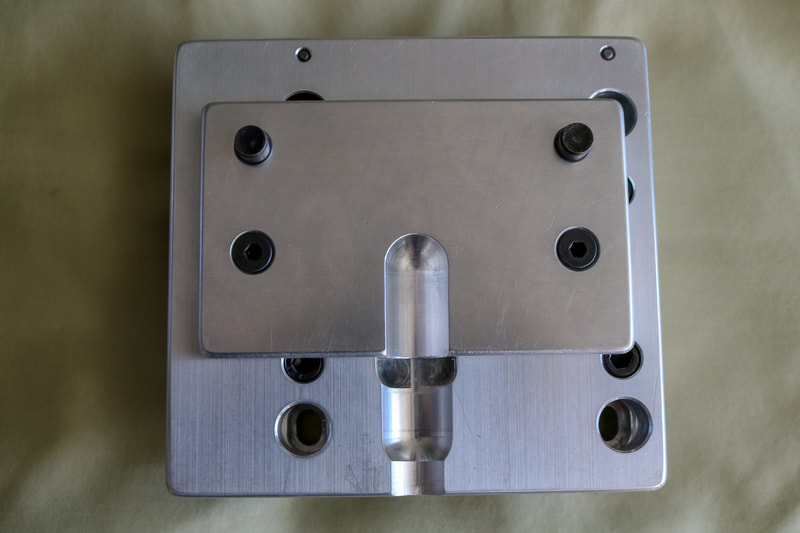

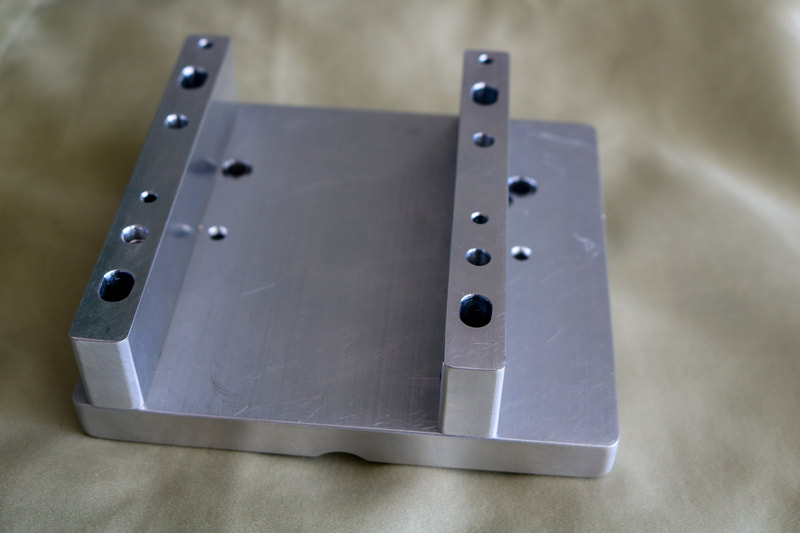

Well, we took some time away from building bicycles to do some custom tooling work for our friends at Schacht Spindle. This die was designed to facilitate insertion of an internally threaded brass part into two different nylon pieces. As such, we had to make two very different top plates to accommodate for each of the two nylon parts and to position them on center with the press. Both the top plates, as well as the legs, are located precisely with one another using dowel pins. The two posts have an eccentric bore that causes them to put pressure on the rear of the top plate when they are tightened, while removing pressure when they are loosened. The above poor image is courtesy of my brand spanking new flip phone! Yes, we take technology seriously here at Wilks Cycles, and only rely on the most up-to-date electronics! In all fairness, my one-year-old smart phone completely failed me, and I was told there was no fix!

If any of you have an interest in beautifully made weaving looms and spinning wheels, take a look at the Schacht Spindle website http://schachtspindle.com (we have both a loom and a spinning wheel)!

4 Comments

|

RSS Feed

RSS Feed